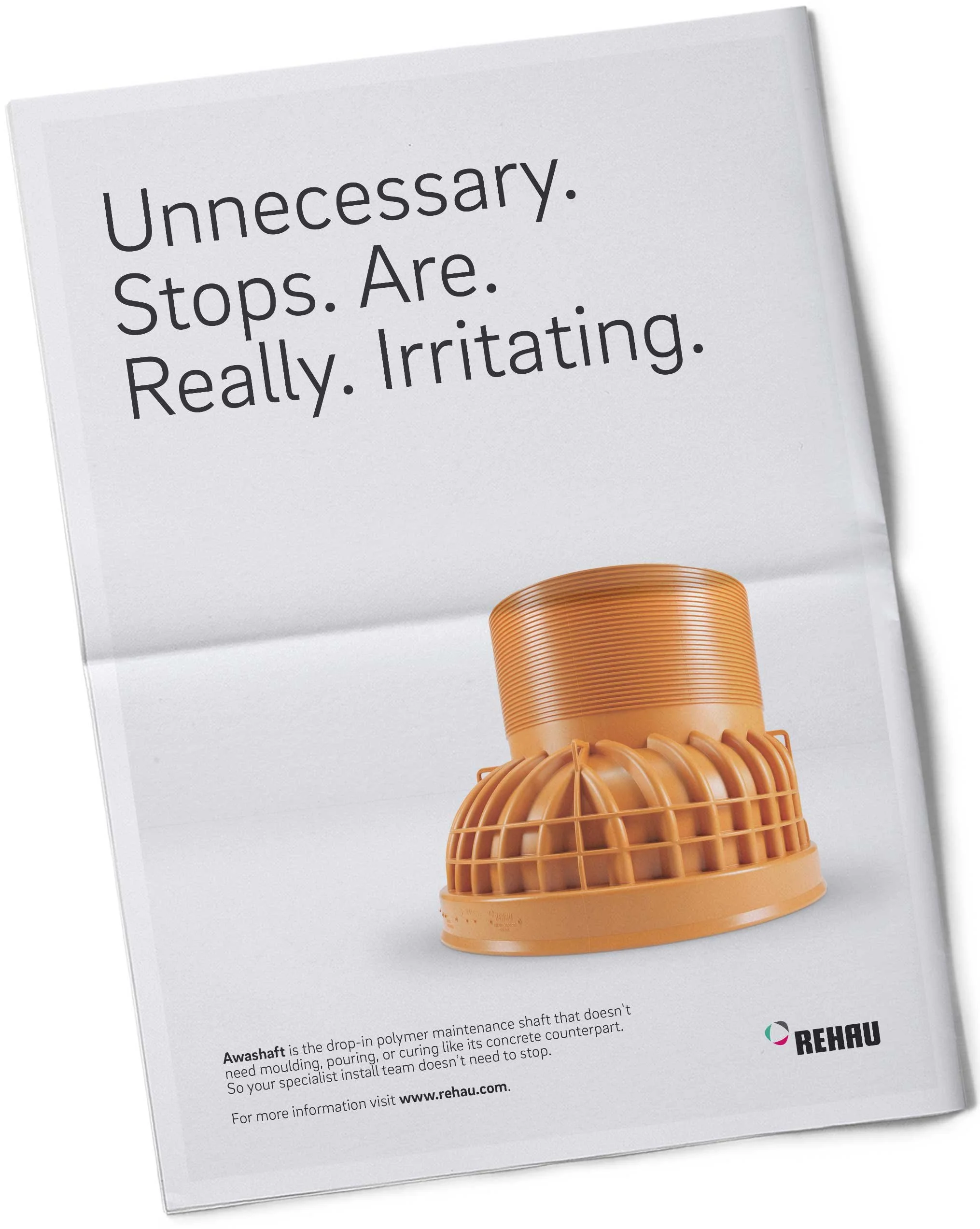

The Headline Demonstration

Using nothing but a packshot and some clever typesetting to demonstrate the benefits of Rehau Awashaft.

The Thinking: Underground maintenance shafts are traditionally made from concrete, which means installing them takes ages and is pretty complicated. But installing Awashaft — a prefabricated, drop-in polymer maintenance shaft — is quick and easy. So team and I at Trout Creative Thinking demonstrated these benefits without spending a dime.

No Production Budget

—

Conceptual B2B

—

No Production Budget — Conceptual B2B —

Stops

The installation of traditional maintenance shafts requires an array of skilled tradespeople — including both builders and concreters — and coordinating them all generally means work stops while one trade subs in for another.

This isn’t the case with Rehau Awashaft.

Gaps

The type of concrete used in the installation of traditional maintenance shafts takes days to cure. This creates a massive gap between when the concrete is poured and when work can continue.

As before, this isn’t the case with Rehau Awashaft.

Speed

The installation of traditional maintenance shafts takes days, as laborious concrete moulds are built from scratch and concrete must be allowed to cure.

Once again, this isn’t the case with Rehau Awashaft.

The artwork shown above remains the exclusive property of the agency or brand it was created for. Modifications may have been made to align with this portfolio’s presentation style and templates.